Menu

Do you know how safe your farm really is? With the busyness of daily farm life, it’s easy to forget about hidden dangers. Farms have many buildings where workers, including the young, often go. Keeping these places safe is key.

The National Ag Safety Database highlights the need for a safe work environment. They recommend using handrails, making sure buildings are sound, and storing hazardous materials properly. This helps keep everyone safe. Rural Mutual also offers help and insurance that focus on farm safety. They believe in taking steps to avoid accidents.

On farms, it’s key to handle and store hazardous materials safely. Many risky substances are used. Knowing about these materials and their risks keeps farms safe and running well.

Farms use dangerous items like lubricants, fuel, and pesticides. They also use items for animal health like medicated feed and antibiotics. It’s vital to manage these materials well to avoid accidents or harm to the environment. Important safety steps involve labelling, securing, and following rules for their storage and use.

The dangers of not handling or storing these substances well are big. Containers might break or wear out, causing hazards. Proper storage keeps animal health products effective. When mixing chemicals, good ventilation and wash areas are needed to stay safe. Farms also must be ready for emergencies. They need plans for how to handle spills or if someone gets exposed to these materials.

Rules like the Integrated Pest Management Act and Regulation focus on storing these materials safely. They do this to protect the environment and health. However, some materials need extra care. Substances like arsenic, fenthion, and strychnine follow very strict rules.

Following these guidelines makes sure hazardous materials are stored safely. This helps keep farms safer.

Storing hazardous materials right on farms is vital. It reduces health and safety risks. It also helps the planet. Farms must follow storage rules and keep materials safely contained.

Farms need safe places to keep hazardous items. This helps avoid bad outcomes. Knowing why this is important lowers dangers.

Handling hazardous items involves big risks. Wrong storage can cause health problems, fires, and more. Making sure things are safe is key:

Badly handled materials harm nature. They can leak into water, causing grave issues. We must prevent this:

By keeping hazardous items in check, farms save both people and nature.

| Aspect | Details |

|---|---|

| Compliance Bodies | OSHA, EPA, DOT, NFPA |

| Necessary Investment | 100% compliance required |

| Best Practices | Using proper containers, clear labelling, storing compatible materials together |

| Consequences of Improper Storage | Health hazards, fires, explosions, contamination, regulatory violations |

Sticking to these pointers helps farms stay safe and eco-friendly.

Storing hazardous materials safely means following strict rules. These rules are there to keep people and nature safe from harm. It’s vital to know and follow these storage rules closely.

The OSHA sets careful rules to be obeyed. There must be warning signs, areas off-limits to some, and locked areas when not in use. Hazardous items must stay away from food, be well-ventilated, and have clear notices to keep trespassers out.

The Hazardous Materials Transportation Act is overseen by the PHMSA. It issues rules in the 49 CFR Parts 100-180 for all shipments since October 1, 1998. You must follow these, even for local shipments, like registering for big amounts of explosives.

Storage for pesticides must be just right to avoid mixing with other items. This means keeping records and creating detailed maps. Always be ready for checks to prove you’re doing it right.

Here are some key regulations to consider:

| Regulation | Details |

|---|---|

| Docket HM-181 | Synchronised US rules on hazardous materials with worldwide standards. |

| Docket HM-200 | Extended hazardous materials rules to local shipments. |

| FMCSA Requirements 2005 | Vehicle safety permits for those carrying high-risk materials are a must. |

| Penalty Maximum | Fines can be as high as $79 per breach. |

| Storage Limits | No more than 25 gallons of flammable liquids can be kept outside special cabinets. |

It’s critical to know and act on these rules. This keeps your workplace safe and avoids accidents. Following these rules helps keep your workers and surroundings secure.

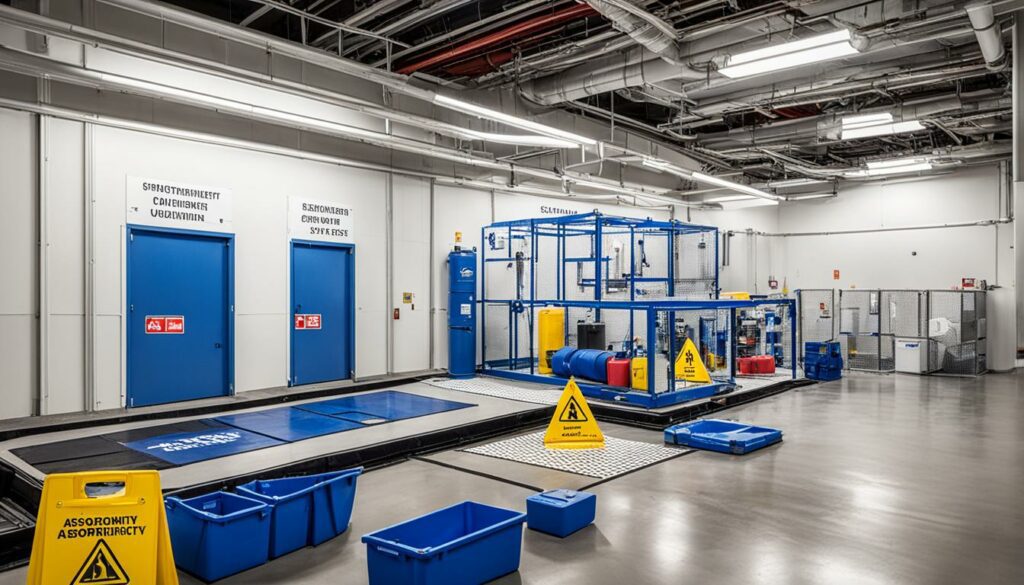

It’s vital to keep storage buildings safe on the farm. Regular checks and updates are key for safe material storage.

Good lighting is crucial in storage areas. It helps workers see clearly and avoid risky accidents. Adequate lighting also means they can read warning labels on materials properly. This can stop them from misusing the materials. Try using lights that turn on automatically when someone walks nearby. This saves energy and keeps places well-lit.

Storage buildings must be checked often to stay safe. Inspections find if the building has any weak spots or damage. This can help prevent serious accidents. Checking upper floors for any issues is very important too.

Keeping the area tidy and well-arranged is also essential for safety. Clean and organised spaces are safer and make essential items easy to reach. Aisles should be wide, at least three feet, as OSHA recommends. Using special locks on machinery can also prevent dangerous starts and injuries.

With thousands of chemicals around, good ventilation is a must. It prevents the build-up of dangerous gases like carbon monoxide. Testing emergency showers and eyewash stations often keeps them ready for use. And, knowing your local emergency responders can help in a crisis.

By following these steps, you can make storing hazardous materials safer. These actions are important for keeping the farm and its workers safe from harm.

Selecting proper chemical storage cabinets is crucial for safety. Consider what types and amounts of hazardous materials you will store. This helps you make the best choice.

Many storage cabinets are available for different needs:

The materials used in making these storage cabinets are very important. They determine how well the cabinets work and how long they last.

It’s also vital that the cabinets meet safety standards. Look for ones that are approved by OSHA, NFPA, and have certifications from FM or UL. This shows they meet high safety standards. By picking the right cabinets for your needs, you can store hazardous materials safely.

Managing a hazardous material facility well is key for everyone’s safety. It’s important to use the right chemical storage methods to avoid health issues and dangerous situations. Improper storage can lead to fires, explosions, and harm to the environment.

Following safety rules from groups like OSHA, EPA, DOT, and NFPA is a must. Not obeying can lead to big fines and trouble with the law. Using UN-approved bags from Palmetto Industries for storing chemicals helps keep things safe. These bags meet the top standards of the UN.

Choosing the right cabinets is crucial. Flammables need special containers, and everything must be clearly labelled. It’s crucial to regularly check for any wear and tear, like leaks. And if you find a problem, fix it right away.

Teaching your workers how to store and deal with emergencies lessens risks. They should know how to use the correct equipment and deal with spills. Segmenting dangerous materials and checking on them often is also important for safety.

Follow these safe storage solutions to cut down on accidents. This way, your hazardous material place will run safely, keeping people and the environment protected.

Proper segregation of hazardous materials is key to a safe storage place. The storage of dangerous substances must be carefully done. Materials are sorted into classes by how dangerous they are. Following these classes helps keep them stored, loaded, and moved correctly and safely.

Segregation is key in hazardous material containment. It’s vital to keep different types of dangerous materials apart. This stops them from mixing and causing harm. For example, you should never store cyanides with acids or Division 6.1 materials with Class 3.

The segregation table is a crucial guide. It tells us how to handle, store, and transport these materials. Following these rules makes sure we keep everyone safe. For explosive materials, there are special rules about which can be together. But, ammonium nitrate can be stored with certain explosives under special conditions.

There are special rules for transporting explosive materials. For example, materials of the same danger level must follow the highest safety rules. These are strict guidelines to keep transportation safe.

Knowing storage limits is crucial. You can’t store more than ten gallons of flammable liquids outside a special cabinet or fridge. Flammable cabinets can only hold a certain amount. And they need to be the right size for the materials.

To make things safer, it’s smart to have extra protection for some materials. Adding extra metal to hold glass bottles, for example, can lower the risk. Using special fridges or freezers for some materials is also advised. And if you store a lot of oxidising chemicals, use a steel cabinet just for them.

Segregation isn’t just a rule; it’s a big step in improving safety. Following these rules ensures hazardous materials are stored in the safest way. This protects everyone and everything on the farm or in the facility.

Effectively managing storage for hazardous materials on a farm is essential. Keeping these areas safe helps avoid risks. It’s vital to keep hazardous material handling separate from food and fertilisers. Storing these materials in dry places stops leaks and protects our environment and health.

It’s key to let only certain people into these storage areas. This limits the chance of someone getting hurt by these dangerous substances. Every worker should know how to store these items and what to do in an emergency. This means they need to learn about safety rules and how to stop spills from causing harm.

Following hazardous storage regulations isn’t just about the law; it’s a must for safety. Groups like OSHA, EPA, DOT, and NFPA ensure farms handle hazardous items safely. NFPA focuses on fire safety for these materials. Not meeting these rules could lead to big fines and other problems. This shows how important it is to follow safety standards carefully.

Some common problems are storing too much of flammable liquids and mixing wrong chemicals. Flammable ones over 10 gallons should be in special cabinets. Corrosive ones should be far from each other to prevent incidents. This stops injuries and health problems.

Keeping good records is also vital. Farms must have clear maps, proper labels, and emergency plans. Labels help avoid mistakes and show dangers to experts. Being thorough in managing these areas leads to a safer farm. It also helps avoid fines and keeps everyone safe.

By sticking to the best ways in hazardous material handling and knowing the latest safety rules, farms can keep storage safe. This protects both people and the natural world.

Keeping farms safe involves knowing how to contain dangerous materials. This keeps the environment safe. Using a solid spill plan cuts down on risks from emergencies.

Farms must ready themselves for hazardous material spills. It’s smart to wait 30 minutes before cleaning aerosolised materials. This lets the particles fall, making it safer to clean up. Staff should manage small chemical spills under a gallon and not flammable. Lab workers are okay to clean up small radiological spills if they follow safety rules. But, big radiological spills need experts to avoid spreading the danger.

Every farm must have a plan for where they store things and emergency water sources. Knowing who can handle hazardous items, especially in a special waste area, is key. These people must have a 40-hour HAZWOPER course under their belt. It’s also essential to keep absorbents like kitty litter close. It speeds up cleaning and helps protect the area.

Quick access to help is a must in any emergency. It’s important that all workers know the emergency plan by heart. This plan should be checked every year by safety experts. Also, knowing first aid is crucial for dealing with minor injuries.

Keeping training records for three years shows the farm is always ready to act. Making sure safety gear like drench showers and fire extinguishers work is essential. These checks should happen every month to keep everything in top shape.

Having a good emergency plan in place, with clear contact numbers and maps, strengthens safety efforts. These steps are a strong defence against the dangers of farm-related hazardous materials.

Using the right chemical storage techniques is crucial. It keeps the farm safe and the materials secure. By storing chemicals in their original packaging and ensuring they are well-marked and sealed, you reduce the chance of harm. This also helps follow safety laws.

Always keep chemicals in their original packaging. This keeps important information visible, such as the product’s name and ingredients. The containers are made to keep the chemicals safe, which means there’s less chance they’ll spill or go bad.

Making sure chemicals are labelled and sealed correctly is crucial. Labels should have the name, safety warnings, and how to handle the chemical. Containers must be sealed well to avoid spills or mixing. Make sure to regularly check for damage or leaks. If you notice any problems, carefully move the chemical to a new container. Always use proper labels to avoid confusion or misuse.

It’s also key to know which chemicals can’t be stored together. For example:

Lastly, using secondary containment can help in case of spills. This method keeps dangerous chemicals from mixing, making the farm safer for everyone.

| Chemical | Incompatible Substances |

|---|---|

| Acetylene | Bromine, Chlorine, Copper, Fluorine, Mercury, Silver |

| Ammonium Nitrate | Acids, Chlorates, Flammable Liquids, Nitrates, Powdered Metals, Sulfur |

| Hydrogen Peroxide | Concentrated Nitric and Sulfuric Acid Mixtures, Acetone |

| Chlorine | Acetylene, Ammonia, Benzene, Hydrogen, Sodium Carbide |

| Nitric Acid (Concentrated) | Acetic Acid, Acetone, Alcohol, Aniline, Chromic Acid, Flammable Liquids |

| Oxygen | Flammable Liquids, Solids, or Gases, Grease, Hydrogen |

| Sodium | Carbon Dioxide, Carbon Tetrachloride, Water |

| Sulfuric Acid | Chlorates, Perchlorates, Permanganates |

Following these chemical storage steps makes the farm much safer for all workers.

Keeping animal health products safe is very important. It protects their quality and keeps animals safe. Always follow the storage instructions on the product label.

Some products, like antibiotics, need to stay cool or they lose their strength. Store them in a fridge between 2°C and 8°C. Vaccines with live parts also need cool storage. Follow the advice on their labels to make sure they work well.

Some items can’t be in the light for long. They come in special dark containers. Using these containers and keeping them away from light ensures they last until the “use by” date. Sorting products by what they are and who they’re for helps avoid mix-ups.

Medicated feed needs clean, dry storage away from other things. Make sure the area meets the product guidelines to keep the feed safe to use.

Buying only what you need of animal drugs helps avoid waste. It’s bad to have too many old medicines around. And when it’s time to throw them out, do it the right way. This is important for everyone’s safety. The same goes for pesticides. Throw away the packaging once you’re done using the product.

Good storage of animal health products and medicated feed isn’t just about keeping things tidy. It helps make sure the farm animals stay healthy. And it keeps the people who care for them safe too.

Keeping pesticides safely is crucial. They should be kept from 40°F to 100°F to work well. It’s important to keep them dry and away from sunlight. This stops them from clumping and losing their power. Storing them in a small space prevents buying too much.

To store chemicals safely, use strong, separate buildings. These buildings are made of metal or plastic. They include plastic trays to catch leaks and lockable doors to keep people out. This setup ensures the chemicals don’t leak out onto the ground.

Where you store pesticides matters a lot. Keep them 100 feet from water sources. This prevents water pollution. Also, keep them away from wells, living spaces, and animal areas. Raising their storage by 12 inches keeps them dry and prevents pollution.

Getting rid of old pesticides the right way is very important. Clean containers three times before reusing them or properly throw them away. Never pour old pesticides into the drain. Always follow local laws for getting rid of them safely.

US Hazmat Storage makes special buildings for storing pesticides properly. These buildings have lights, fans, and systems to fight fires. They are very secure and can be customised to suit your needs. They meet safety standards set by the government.

| Parameter | Specification |

|---|---|

| Temperature Range | 40°F – 100°F |

| Material | Nonabsorbent (Metal/Plastic) |

| Floor Type | Sealed, Nonabsorbent (Concrete) |

| Distance from Surface Water | At least 100 feet |

| Elevation | 12 inches above ground level |

| Structural Warranty | 20 years |

Keeping fuel and lubricants stored safely is key to farm safety. OSHA rules make sure areas are safe. They require aisles to be clear and containers to be tough and checked often.

OSHA and NFPA have very clear rules for storing these items. Tanks must be at least three feet apart to prevent any mixing risks. Good air flow is a must to stop vapours from building up.

There are different rules for storing flammable liquids. Gasoline and acetone, known as Class I, must be kept away from fire threats. However, motor oil and ethylene glycol, Class III liquids, need different care as they are less likely to catch fire.

Putting the right label on things is vital. It helps people spot dangers fast. It’s important to use the right containers, for example, metal for some types and avoiding others for flammable liquids.

Material Safety Data Sheets (MSDS) offer key safety details. By following the rules and keeping an eye on storage, we make sure everything is as safe as possible.

| Class | Examples | Storage Requirements |

|---|---|---|

| Class I | Gasoline, Acetone | Separation from ignition sources, solid containers. |

| Class II | Diesel Fuel, Jet Fuel | Away from high-heat environments, regular ventilation. |

| Class III | Motor Oil, Ethylene Glycol | Solid, corrosion-resistant containers, regular inspections. |

Storage of hazardous materials on farms requires detailed planning and following strict rules. They can include chemicals, gases, and flammable liquids. They must be stored in ways that prevent accidents and keep everyone safe.

Choosing a safe storage facility is crucial. It needs good ventilation, temperature control, and systems to handle spills and fires. Everything should be labelled clearly, with warnings on where things are stored. This ensures different dangerous items are kept apart to avoid harm. Workers must also wear the right protective gear.

To manage these areas well, farms need special equipment and regular checks. They should also have emergency plans in place and make sure everyone knows how to stay safe. Good training and following all the safety rules keep the farm, its workers, and the environment safe. By working hard and staying informed, farms can handle hazardous materials well.

To store hazardous farm materials safely, use well-labelled and well-ventilated areas. Always follow OSHA guidelines and pest management rules. Materials like lubricants and pesticides should be kept in special cabinets. These cabinets must meet safety standards for their content.

Farms use many hazardous products such as lubricants, fuel, and pesticides. They also use animal health products like medicated feed and antibiotics. It’s important to know about these products to manage risks well.

Good storage reduces the risk of health, safety, and environmental issues. It helps follow laws, stops accidents, and keeps dangerous substances safe. This is why storing hazardous materials correctly is very important.

To store hazardous materials safely, follow OSHA and pest management rules. Use warning signs, limit access, and keep the place well-ventilated. Also, always have MSDS records. These steps make sure storage is safe.

**A**: Good safety steps for storage buildings include keeping the area well-lit. Check the building’s safety regularly and keep the area tidy. It’s also essential to have stable floors, good ventilation, and to use lockout tagout when needed.

**A**: First, know what materials you have and will store. Classify them by their danger. You should buy cabinets made of strong materials like steel or polyethylene. Make sure they fit legal requirements and are spill-proof.

Segregation stops chemical reactions and mixtures that could be harmful. Store different types of hazardous materials like flammable substances away from each other. This helps lower the risk they pose.

Keep storage areas away from food and fertilisers and secure them. Only allow authorised people to enter. Keep good records and have plans for emergencies. This will make managing the area easier and safer.

For spills, have the right materials like kitty litter ready, and a clear plan. Make a list of emergency contacts and have absorbent materials at hand for fast cleanup. This is key to protecting the environment and staying safe.

Chemicals must be kept in their original containers with clear labels. They should seal well and you should check them often. If you need to change the container, label it properly. This keeps everyone safe and informed.

Store animal health products in a clean, dry place, away from others. Some might need cold storage to stay effective. Follow any specific storage directions on the product label.

Pesticides need to be in secure and well-marked places, with good airflow. Keep them away from other chemicals and treated seeds. Also, follow rules for pest control and use the right warning signs.

Keep fuels and lubricants in tight, leak-proof containers. Store them in a dedicated place, not with other hazardous materials. Always label them well and check for leaks. Have a plan for how to handle spills.